Thermal mapping and validation

At Gometrics we have a thermal mapping and validation service oriented to any field of industry where it is necessary to document temperature cycles: qualification of autoclaves, ovens, depyrogenation tunnels, climatic chambers, incubators, stoves, vacuum stoves, freeze dryers, refrigerators, freezers, deep freezers, raw material or finished product warehouses, refrigerated vehicles.

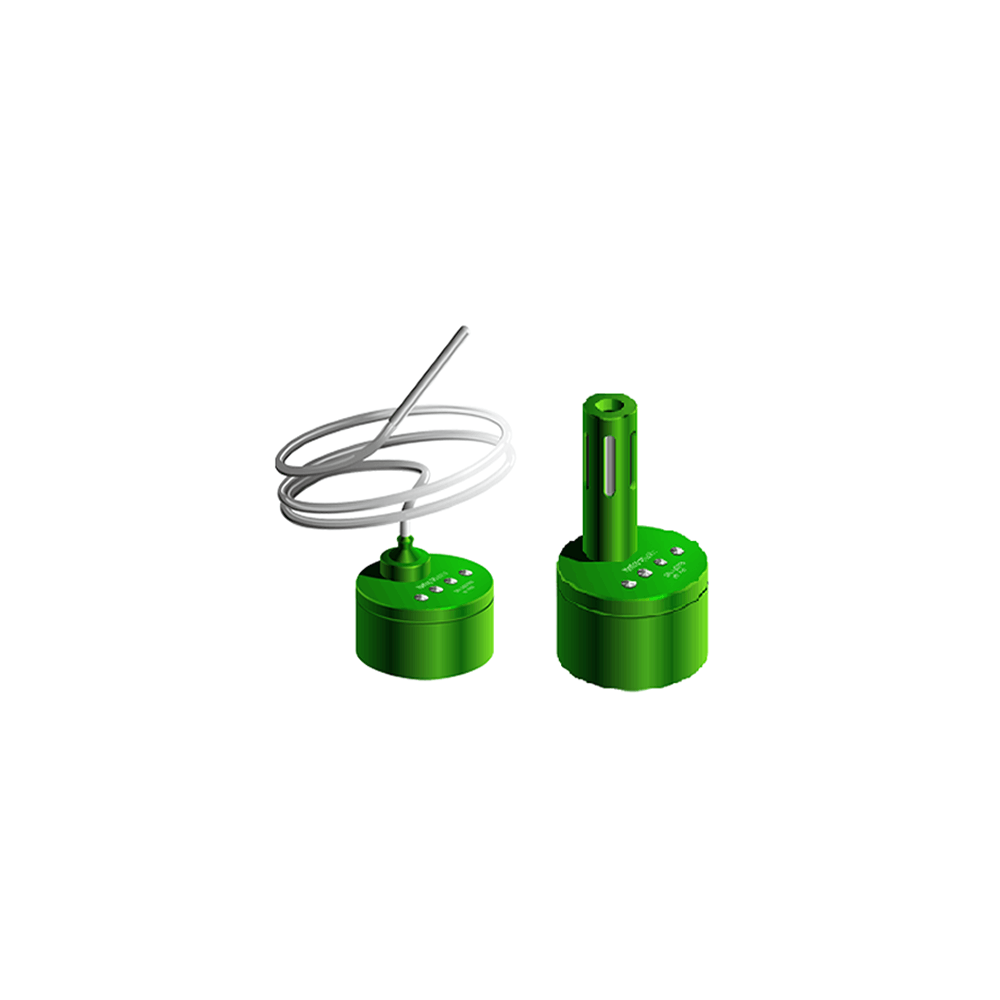

All these services are provided with highly accurate and 21 CFR Part 11 compliant software and dataloggers, widely accepted in the pharmaceutical industry. ENAC calibrated.

These systems are contrasted with calibrated standards and placed in strategic points of the enclosure to accurately monitor the parameters to be controlled. They are easy to install and offer maximum flexibility and reliability in data collection.

To perform these thermal validations, Gometrics has a multidisciplinary and well-trained team of professionals, who can not only perform the requested study, but also provide the customer with their knowledge to improve their processes.

Which teams do we qualify?

Study of vacuum operation (sufficiency of programmed cycles, Bowie Dick test, leak test), steam penetration studies in the different loads, calculation of lethality index F0, biological indicators.

Qualification cycles in vacuum to study the correct temperature distribution and cycles with different loads to study the penetration and maintenance of heat, verification of the correct reduction with endotoxins.

Of the production cycles with their different phases, studying the temperature distribution on the surface of the trays using probes specially designed for this purpose. The sterilization cycles (SIP’s) inside the chamber, filters, … are also qualified.

Drafting and execution of protocols for the qualification of the installation, operation and process, with the corresponding thermal mappings in vacuum and under load, and agreed defined tests (alarm test, open door test, power failure test, etc).

Thermal mapping of warehouses and cold rooms, as well as the qualification of vehicles (vans and trucks) for the transport of medicines in controlled conditions (2 to 8ºC) and (15 to 25ºC). Determination of hot and cold spots for subsequent continuous temperature monitoring. Qualification of transport routes.

Qualification cycles in vacuum to study the correct temperature distribution and cycles with different loads to study the penetration and maintenance of heat, verification of the correct reduction with endotoxins.

For these thermal equipment mentioned, option of drafting and execution of validation protocols (DQ, IQ, OQ and PQ) as well as advice in drafting URS and RA’s.

Likewise, our ENAC accreditation allows us to offer the service of test reports in thermal characterizations in isotherms (stoves, incubators, refrigerators, climatic chambers, autoclaves, ultracolders -80 ºC, etc.).

We are ENAC certified in the magnitude of Temperature.

Recommended products